ASTM D 4169 Test

History and background

- A “world-wide accepted” packaging standard is the:

ASTM (American Society for Testing and Materials) international D 4169 Performance of shipping containers and systems. - Therefore Sebert Trillingstechniek, an accredited ISO 17025 test laboratory, use this ASTM standard as the guideline to specify the test-procedure for the packaging’s.

Test Procedure

- Within this chapter the test-procedure for a single-packaging and a combination of pallet-packaging’s will be determined and clarified. As stated before the ASTM standard D4169 is the one to start from.

- Section 8 describes the complete procedure to achieve an uniform basis of evaluating, in a laboratory, the ability of shipping units to withstand the distribution environment.

Define Shipping Units

- Describe shipping unit in terms of size, weight, and form of construction.

- Determine of the shipping unit will be manually or mechanical handled.

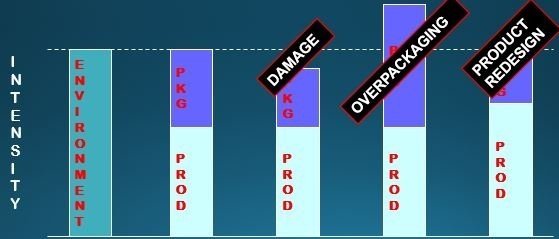

Determine Acceptance Criteria

In many cases, the acceptance criteria can be the following:

- Criterion 1 – Product is damage-free

- Criterion 2 – Package is intact

- Criterion 3 – Both

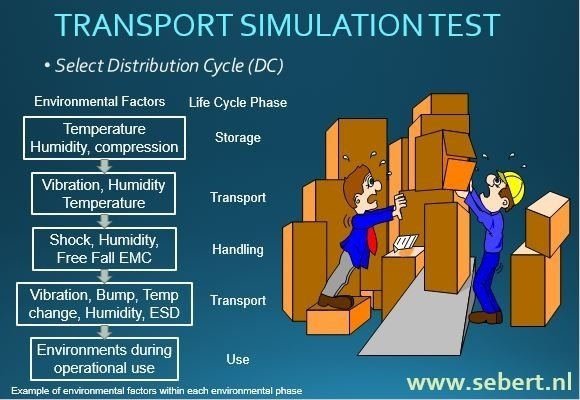

Select Distribution Cycle (DC)

- Out of table 1 of the ASTM D 4169, DC should be chosen which correlates to the projected distribution. This is categorized from DC 1 till DC 18.

Select Distribution Cycle (DC)

Out of the test schedule the complete test-procedure is derived:

- Schedule A (Handling Impact Test) is described in section 10.

- In this case (see paragraph 8.1) a single packaging or a combination of pallet packaging’s are supposed to be handled manual or mechanical from the distribution centre to the “end customer”.

- Schedule D or E (Random Vibration Test) is described in section 12.2.

- Underneath section 12.1 the random test is considered to be the preferred one. Recommended intensities and durations are given in 12.4.

- If only one single packaging is available and you will simulate a pallet packaging then it is recommended to put a concentrated load as calculated in section 11.4. This test is also called Schedule C Vehicle Stacking plus vibration.

- See Annex A below in this presentation for more information about the changed truck vibration profile and how to accelerate the test time of the simulations.

Select Distribution Cycle (DC)

- Schedule F (Sine Vibration Test) is described in section 13.1.

This test determine the ability of the shipping unit to withstand the repetitive shocks occurring during transportation of loose loads. For example whipping/slamming of a boat or a bad way.

- Schedule J (Concentrated Impact Test) is described in section 17.1.

This test provides a simulation of anticipated low level concentrated impacts as received by packages during sorting operations and in transit.

- Schedule A (Handling Impact Test) a repeated as described before

Only for the single packaging is the last impact of the last manual handling sequence different. The impact should be made at twice the specified height. This is the final drop in the sequence (not an additional drop). The drop should be in the impact orientation most likely for a drop to occur, usually the largest face or the bottom. For distribution cycles where any drop orientation is possible, this drop should be in the most critical or damage-prone orientation, as define in test Method D 5276.

Select Samples for Test

Tests specimens consist of representative samples of complete shipping units, including actual contents. Products with blemishes or minor defects may be used if the defective component is not to be studied by the test and if the defect is documented in the report.

Condition samples

Normal condition to 23 +/- 10C, 50 +/-2 % relative humidity with a (pre)conditioning of 72h is recommended for samples which are sensitive for temperature and humidity.

It is also possible to carry out the (vibration) test under -40°C till +70°C, in combination with till 95% humidity.

Perform tests

Perform test in accordance with a test plan (see below Write a Test Plan) and following up the special instructions for each test schedule.

Evaluate Results

Evaluate results to determine if the shipping units meet the acceptance criteria as defined.

Document Test Results

Document test results by reporting each step.

Monitor shipments (important)

When possible, obtain feedback by monitoring shipments of the container that was tested to ensure that the type and quantity of damage obtained by the laboratory testing correlates with the damage that occurs in the distribution cycle. This information is very useful for the planning of subsequent tests of similar shipping containers.

Additional tests

Climate Test

It is possible to carry out a vibration test in combination with low temp (-40°C) in our laboratory or high climate 45°C with 95% RH (Hong Kong).

Under pressure test

It is possible to carry out a low pressure vibration test in combination with climate conditions in our ISO 17025 accredited laboratory.

Additional information

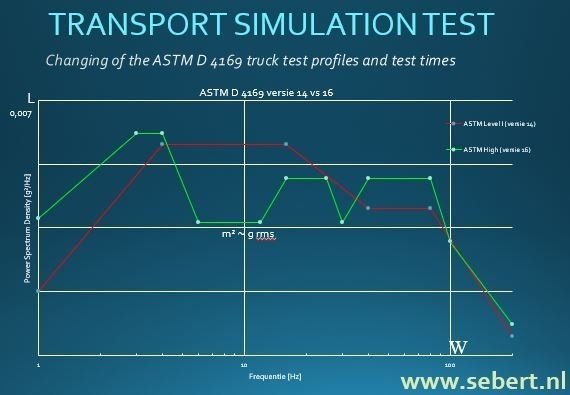

Annex A

Changing of the truck random vibration profile

- June 2016 the ASTM D 4169-14 is replaced into ASTM D 4169-16.

- The biggest change in this version is paragraph 12.4 a reduction of the stress intensity level of the truck vibration test profile.

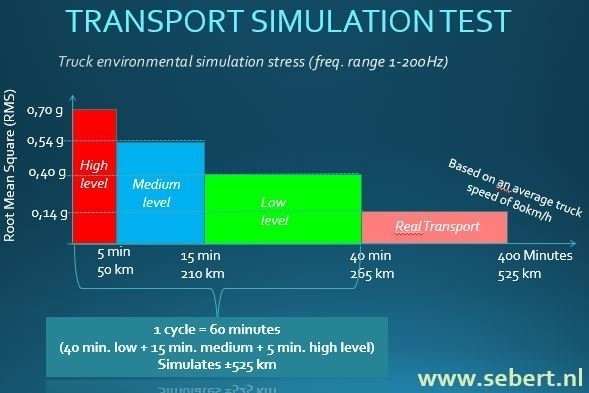

- The truck assurance level I-III is replaced into Low => High

- Test time is changed into Cycle testing (1 hour ~ 525 km)

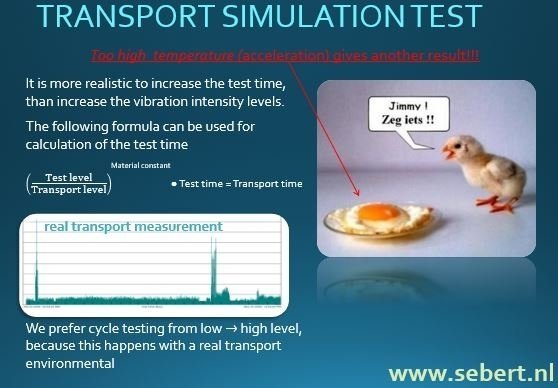

Accelerated testing

- Increase your test time is more realistic than increase the vibration intensity levels.

ILAC ● MRA Logo

Why is there an ILAC•MRA logo on the report?

ILAC stands for International Laboratory Accreditation Cooperation. The European Union (EU) has entered into mutual recognition agreements (MRAs) with various countries. This means that the countries have to accept each other’s products. When you select our accredited laboratory for a test report or certificate, this will feature an ILAC • MRA logo. This report will then be accepted by all participating EU countries, but also by the United States, Japan, Australia, Canada, Israel, New Zealand and Switzerland. This fulfils the free trade objective of “a tested product which is accepted anywhere”. You can avoid the bureaucracy, and don’t have to carry out tests in each country.

What is the added value?

Sebert Trillingstechniek is accredited by the Dutch Accreditation Council (RvA). The RvA is part of European Accreditation (EA). As the Recognized Regional Cooperation Body, EA is affiliated with ILAC. The RvA is a full member of ILAC: http://ilac.org/ilac-membership/

If tests are carried out by an ISO 17025-accredited test laboratory, ILAC recognises and accepts accredited tests worldwide, which is not possible if the tests are carried out by an ISO 9001 or ISTA test laboratory. The technical aspect of the ISO/IEC 17025 standard relates to the use of qualified and experienced staff. All test equipment has been calibrated and checked in accordance with the ISO/IEC 17025 standard. Validated methods are also used for testing, recording and reporting of results. This ensures that the tests, obtained in an independent, professional and objective manner, are extremely reliable. You also have certainty about the quality of the test results.

Referenced documents

- Six step method from Lansmont Corporation

- Environmental Engineering Handbook from Swedish Environmental Engineering Society

- Transportation Stresses from Committee of European Environmental Engineering

- Societies Department of Defense Test Method Standard MIL-STD 810 F

ASTM Standards

- D4169 Standard Practice for performance Testing of Shipping Containers and systems

- D996 Standard Terminology of Packaging and Distribution Environments

- D5276 Standard Test Method for Drop Test of Loaded Containers by Free Fall

- D880 Standard Test Method for Impact Testing for Shipping Containers and Systems

- D6179 Standard Test Methods for Rough Handling of Unitized Loads and Large Shipping Cases and Crates

- D999 Standard Methods for Vibration Testing of Shipping Containers

- D4728 Standard Test Method for Random Vibration Testing of Shipping Containers

- D6344 Standard Test Method for Concentrated Impacts to Transport Packages